A perforated sheet is a sheet of material, such as metal that has been mechanically or chemically punched or drilled with holes or patterns. These holes or patterns can be of various shapes, sizes, and spacing, depending on the desired application.

Perforated Sheets Manufacturer India

Fine Perforators, a born to lead perforated sheets manufacturer in India, offers the widest range of perforated sheets of different metals. Our commitment to becoming an innovative and cost-efficient perforation solution provider of your choice guides us to advance our infrastructure, facilities, and technologies continuously. As a result, we have world-class facilities to offer custom made perforation designs that suit the best to your applications.

Quality Adhered Perforated Sheets Producer and Supplier

We endeavor to provide customized perforation solutions and aligned services as a one-stop store to meet out all your diverse needs. As a pioneer perforated sheets producer and supplier in India, we follow the robust quality standards to support your growth plans. For us, customer satisfaction is the top priority; therefore, we infuse creativity, quality and technology into our service model designed and regularly refreshed to deliver 100% customer satisfaction.

Perforated Sheets with Cost Benefits

The perforated sheet price is a primary concern of manufacturers and other users. The genuine price and guaranteed quality drive the users to think for innovative perforated sheet uses to remain ahead of competitors. During our journey since 1969, we have created numbers of quality benchmarks for the perforated sheet manufacturers in India. The competitively priced large product line with round perforations, square perforations, slotted perforations, staggered perforations, zone perforations etc not only brings you the cost benefits, but, the multiple benefits of dealing with an industry leader also.

A Dependable Perforation Company for All Types of Materials

Metal sheet selection determines the sheet's strength, hardness, and resistance to corrosion/abrasion/environment impacts etc. Our world-class perforation facilities make us capable to deal with any perforation requirements irrespective to the material composition of sheets; may it be stainless steel (SS), brass, aluminum, mild steel-MS, alloy steels, galvanized steel, titanium, cast iron, copper, plastic, amorphous, anode metal, bimetals, brass, bronze brazing alloys or any other material. We don’t impose limitations on your production plans; therefore, you will find us as the best dependable supplier of perforated sheets even of metal matrix composites, tungsten alloy, molybdenum alloys, and non-ferrous metals etc.

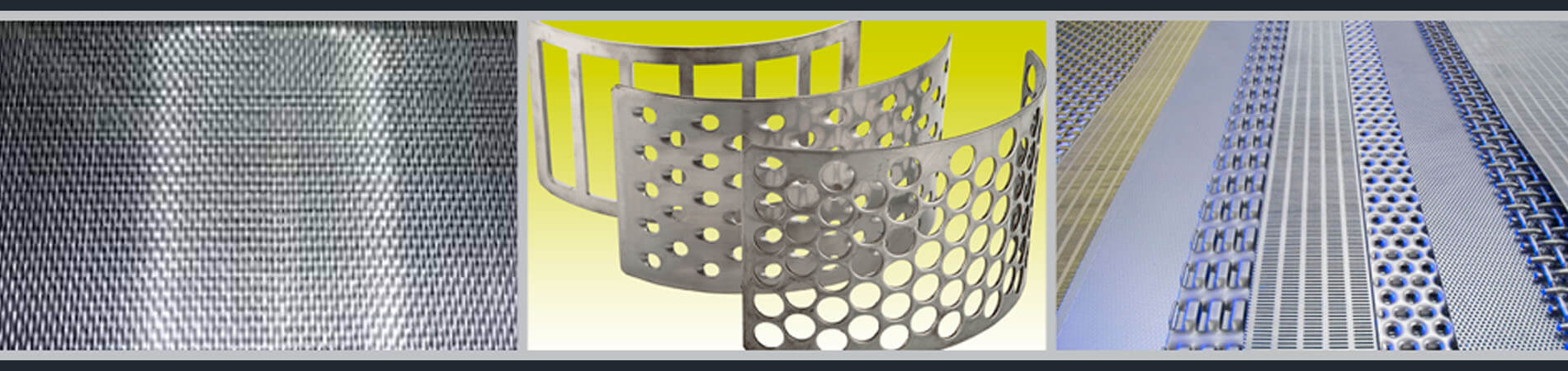

Types of Perforation - Perforation Goes Trendy at Fine Perforators

As the end-users are getting more conscious about the quality and aesthetic look of products, manufacturers need more diversity perforation pattern. As being an ISO 9001:2008 certified company, we offer the best finish with each perforation pattern to make your product trendy.

Our advanced perforation machinery and technology allow you to grace any metallic or non-metallic sheet with a designer look with cost and performance benefits. We welcome you to explore our perforation experience, expertise, capabilities creative ideas to adore the required sheets with diamond shape holes, round holes, square holes, hexagonal holes, triangular holes, non-standard decorative holes, rectangular holes, and others. Also, you can opt for the holes pattern like staggered or straight. As being the top perforated sheets manufacturers in India, we offer a wide range of hole-sizes with industry-best customization facilities.

Applications of Perforated Sheets in Different Industries

Perforated sheets/ plates/ screens are finding new applications in more industries crushing the traditional boundaries. Sugar, chemical, food processing, oil, pharma, paper products, construction, mining, architecture, automotive, equipment manufacturing, agriculture & other industries have been the traditional major users of perforated sheets. The decorative industry is also using the perforation technology to improving natural lighting, ventilation, and cooling systems in buildings for reduction in energy consumption.

Top Perforated Sheets Exporter in India

Over the five decades, Fine Perforators has become one of the top-ranking perforated sheets exporters in India. As of today, we are exporting the quality best-perforated sheets to Dubai, Philippines, Thailand, Vietnam, Pakistan, Bangladesh, Iran, Mexico, Jordan, Malaysia, Sri Lanka, and Indonesia etc. Our customer-centric approach and so far performance is guiding and empowering us to expand the list of countries in our portfolio.

Our large storage helps us to maintain consistency in supply while the advance perforation capacity helps us to meet out your diverse demands at the earliest in the line of your requirement. Our strategically developed network of channel partners all across India and in other continents makes the complete export and import processes hassle-free. Our experts are just a call or email away to help you at any stage – the selection of the best, buying cheap or smooth delivery.

Perforated Sheets Export Product Details

| Country of Origin | Made in India |

| Brand | Fine Perforators |

| Material Grade | MS, SS, Aluminum, Brass, Copper |

| Size | As per Buyer Requirement |

| Usage/Application | Industrial |

Why to Choose Fine Peforator for Your Perforated Sheets Export Requirements from India

- Efficient Export Logistics Management streamlining order handling, transportation,

inventory management to clearance of the export goods - Worldwide Competitive Price for Perforated Sheets

- Best-in-class Engineered Perforated Sheet Product

- Over 50 Years Production Experience of Perforated Sheet

- Fast & On-Time Shipment from Inland Container Depot ICD Delhi / Sea Port Mumbai

- Secure and Safe Packaging

- Modern Warehousing Facilities

- 24x7 Support by Mobile/Phone/Fax/Email

Contact us for Perforated Sheets Requirements

Frequently Asked Questions

Perforated sheets can be made from a wide range of materials, including metals such as stainless steel, carbon steel, aluminum, brass, copper, and others. The choice of material depends on factors such as the desired strength, corrosion resistance, appearance, and budget for the specific application.

Perforated sheets have a wide range of applications across various industries, including architecture and design, automotive, HVAC, filtration, acoustic panels, agriculture, food processing, mining, oil and gas, electronics, and many others. They can be used for purposes such as screening, filtering, separating, ventilating, shielding, decorative elements, and more.

Yes, most perforated sheet manufacturers offer customization options to meet specific requirements. This can include customization of hole size, shape, spacing, pattern design, sheet size, material type, and finish. Customization allows for tailored solutions to meet the unique needs of different applications.

When selecting a perforated sheet manufacturer, it is important to consider factors such as their experience, expertise, reputation, quality of materials and fabrication, capabilities for customization, lead times, pricing, customer service, and after-sales support. It is also essential to ensure that the manufacturer complies with relevant industry standards and regulations.

Yes, perforated sheets can be coated or finished to provide additional properties such as corrosion resistance, aesthetics, durability, and more. Common coating or finishing options include powder coating, anodizing, plating, painting, and other specialized coatings, depending on the material and application requirements.

Selecting the right perforated sheet for your application involves considering factors such as the material type, hole size, hole shape, spacing, pattern design, sheet size, and finish. It is important to understand the specific requirements of your application, including the intended purpose, environment, performance expectations, and budget. Consulting with a perforated sheet manufacturer or a qualified engineer can help determine the best solution for your needs.

The lead time for manufacturing perforated sheets can vary depending on factors such as the complexity of the design, customization requirements, quantity, and the manufacturer's production capacity. It is important to inquire with the manufacturer about their lead times and plan accordingly for your project timeline.

Yes, some perforated sheet manufacturers may offer additional services such as fabrication, assembly, welding, bending, cutting, and other value-added services to provide a complete solution for specific applications. It is important to inquire with the manufacturer about the additional services they offer, if required for your project.

Considerations for perforated sheet installation include proper attachment and fastening methods, adequate support structure, careful handling to prevent damage, and adherence to safety measures recommended by the manufacturer or industry standards.

Calculating perforated sheets involves determining the desired hole size, shape, spacing, and pattern design based on the specific application requirements, and consulting with a perforated sheet manufacturer for their capabilities and customization options.

The price of perforated metal varies depending on factors such as material type, thickness, hole size, hole shape, spacing, pattern design, sheet size, finish, quantity, and manufacturer. It is recommended to request quotes from different manufacturers to get an accurate price for the specific perforated metal product needed.

The thickness of perforated sheet can vary widely depending on the material type, application requirements, and customization options. Common thicknesses for perforated sheet range from 0.5 mm to 6 mm, but thicker or thinner sheets may also be available depending on the manufacturer's capabilities and the specific application needs.

The cost of perforated metal can vary depending on factors such as material type, thickness, hole size, hole shape, spacing, pattern design, sheet size, finish, quantity, and manufacturer. While perforated metal can be more expensive than plain sheet metal due to the additional processing and customization involved, it is recommended to request quotes from different manufacturers to get an accurate cost for the specific perforated metal product needed.