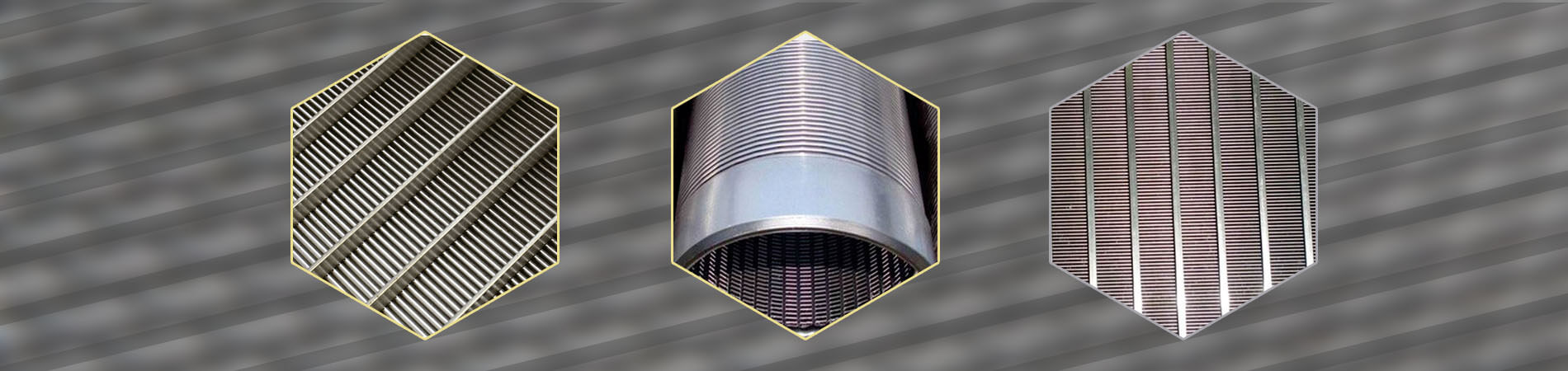

It is a multi-functional screen widely used because of its clogging resistance and toughness characteristics. It is made of support rods and wires. The combinations of various kinds of support rods, different wire profiles, range of slots, and types of flow direction create a wide range of wedge wire screen suitable for different applications in the industries including water treatment, food processing, beverage, oil & gas, pulp & paper, mineral etc.

Top Indian Manufacturer & Exporter of Wedge Wire Screen

The wedge wire screens are finding increasing applications across diverse industries like mining, food processing, chemical, cement, sugar, architectural, gas & oil, paper etc. These are primarily used for separation, sizing, and filtration of food, water waste, liquid/gas, metal particles, mining materials etc. Fine Perforators, the performance-oriented manufacturer, supplier, and exporter of wedge wire screens, offers a wide range of wedge wire screens for sale with a commitment to offering the best quality at the lowest price to contribute to your competence and growth. Our moreover twenty years experience in the export of wedged wires screens makes us a dependable source to buy the genuine wedged wire screens that go through the robust quality checks strictly in the line of international specifications.

Material Composition of Wedge Wire Screen

Wedge wire screens are made of stainless steel (SS) wire. The SS rods support the rigidity and strength of wedge wire screens. The special design of wire knitting/loops makes the top opening narrow while the bottom opening is comparatively wider that keeps the flow rate high as required by the industries. The V shape of the wedged wires makes these screens clogging resistant and tough. The surface profile is designed to maintain synchronous filtration flow. We, as being one of the top wedge wire screen manufacturers and exporters in India, offer the widest range of wedged wire screens including fine surfaced welded wedge wire screens starting from 0.25mm slot size. To ensure you the maximum productivity with the least cleaning requirements, we help you to find the best suitable wedged wire screen for the particular application according to:

- Use

- Dimensions

- Material

- Profile

- Rods, slots & grooves

- Capacity for the particular application

Advantages of Using Wedge Wire Screens

- These have a wider circulation area comparative to other screen types

- These have excellent mechanical strength

- These screens are corrosion and abrasion-resistant

- These are good to use in harsh environment and high temperature

- These adapt different incoming-fluid directions easily

- These are time tested for providing consistency in filtration accuracy

- These can be reused for a long repeatedly

- These are smoothly finished assuring no dead-ends inside

Fine Perforators Offers Wedge Wire Screens for Every Application

The selection of wedge wire screens mainly depends upon the particular application; we as the prominent wedge wire screens exporter have in-depth knowledge of refining, screening, and filtration processes. Our ever-expanding range of quality guaranteed wedge wire screens can be categorized based on applications type:

- Wedge wire filters – Commonly used in filtration devices for liquid and particles filtration

- Intake screens – Used at intake of seawater for purification

- Water well screens - Used in water wells to filter out the sediments

- Architectural wedge wires screens – Used for wall cladding and building facades

- Wedge wire gratings - Often used at drainage ditch covers

- Wedge wire screen for support grids – Used at the bottom of de-sulfuring machines, carbon filters, sand lautering tanks etc.

- Wedge wire sieve bends – Used in sieve bend filtering screens

- Wedge wire screen baskets - Rotate at a high speed for solid-liquid separation

- Wedge wire screen cylinders – Used in heavy-duty large-sized machines because of high load carrying capacity

- Rotary drum screens – Used in drum screens driven by motors

- Looped wedged screens – Made from round wire looped at regular intervals; Used in mining, processing, chemical, sugar industries

- Stationary wedge wire screen - Made of looped wires assembly or welded wires, these screens are commonly used in sugar, mining processing, cement industries etc

Why Choose Fine Perforators as Wedge Wire Screens Exporter

Fine Perforators is continuously advancing its facilities to meet the diversity in the growing international demand; as a result, we are uniquely positioned to design, manufacture, supply, and export the wedge wire screen for your particular application. Each wedge wire screen product, we manufacturer and supply, is tested to maximize the efficiency of wedge wire screen machines; therefore, you get the best worth of investment in terms of product, performance, and productivity.

We have adequate arrangements to maintain the consistency in supply through our nationwide and international network with fixed responsibilities including addressing the concerns of our Indian and offshore customers. Our customer-centric approach and culture to adapt the latest technology at the earliest make us the #1 manufacturer and exporter of welded wedge wire screens and wedge wire screens in India. We are confident to transform your so-far experience of buying any type of wedge wire screen for trading, processing or manufacturing purpose. Just a call to our experts will make you believe our technical excellence and competency in manufacturing, supplying, and export of the quality best wedge wire screens.

Contact us for Wedge Wire Screen Requirements

Frequently Asked Questions

As the demand of wedge wire screens is increasing, the manufacturers of wedge wire screen are expanding the variety also. The more commonly used wedge wire screen types are:

- Wedge wire screens

- Welded wedge wire screen

- Stainless steel wedge wire screen

- Wire stainless steel pipe screen

- Looped wedge wire screens

- Parabolic screens

- Hydropower screens ……more

Yes, we export an equally wide range of centrifugal screens, Nickel Screen, perforated sheets, wire mesh, wire screens, vacuum filter screens etc also.

Although we offer wide range of custom design of wedge wire screens for diverse applications all across the industries; yet, we facilitate our customers to have the wedge wire screen of particular specifications for a specific application.

The looped wedge wire screens are used to separate undesired materials from the parent materials such as smaller size materials mixed with bigger size materials or solids suspended in liquids. The wedge wire design comprises of individual wires loops held at place with cross-rods through a machine. Self-cleaning, stronger than wedge welded wire screens, tilted effect for high water filtration etc are the salient benefits of looped welded wedge wire screens.