Wire Mesh Manufacturer & Exporter India

Welcome to Fine Perforators, the pioneer wire mesh manufacturer and exporter in India having the world-class facilities to meet the diversity enriched demand of different business sectors. Our dedication to manufacture the quality best wire mesh screens and to export at unbeatable prices makes us a class apart. We offer not only the widest range and the best quality of woven wire mesh and welded wire mesh at the cheapest price but also the comprehensive pre-sale and post-sale support.

Woven Wire Mesh Screens vs Welded Wire Mesh Screens

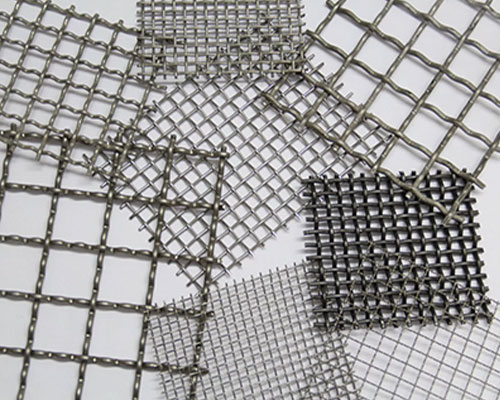

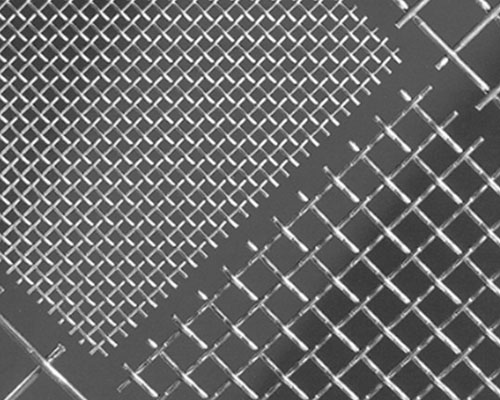

The woven wire mesh panels/screens are woven with various kinds of metal wires like stainless steel, aluminum, brass, copper, alloys, tungsten, and molybdenum etc. Some points are welded to make it durable but flexible to a certain extent. All the woven wire mesh sizes provide a cost advantage because of the low production cost. Its major application is in irregular contoured shaped screening/filtration machines.

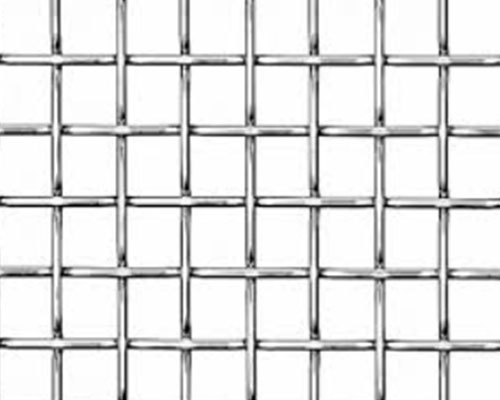

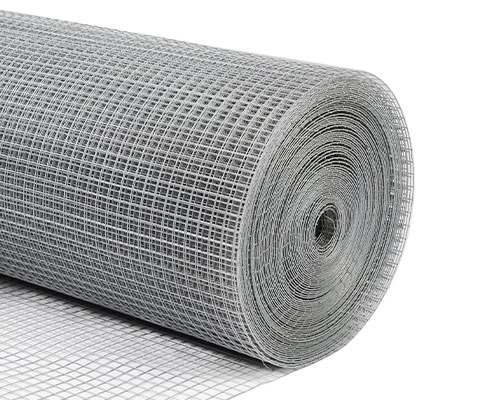

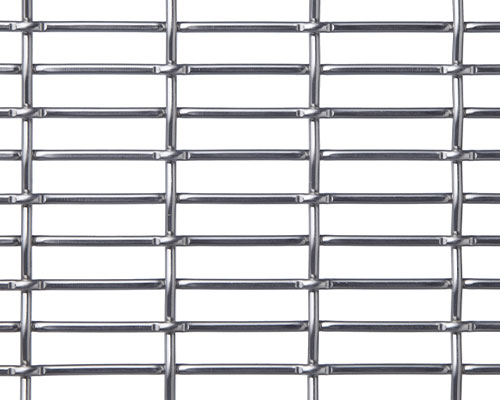

The welded wire mesh screens are welded at all the intersecting joints that make it rigid to hold a uniform shape even under high pressure. These can withstand high pressures without tearing or change of shape. These are more useful for applications that need daily cleaning. The welded wire mesh panels/screens are galvanized to get higher strength and environmental resistance.

Types of Wire Mesh